Top 5 Industrial Automation Trends of 2025

- DelaControl

- Sep 18, 2025

- 2 min read

Industrial automation continues to evolve rapidly, driven by new technologies, shifting global supply chains and increasing demands for efficiency. As we move through 2025, manufacturers and engineers are adopting innovative solutions that reshape how factories and process plants operate. Here are the top five trends set to define automation technology 2025.

1. AI and Predictive Maintenance

Artificial intelligence is moving beyond pilot projects and becoming part of daily operations. Predictive maintenance powered by AI-driven analytics allows companies to spot potential failures before they cause costly stoppages. By analysing vibration data, energy consumption and temperature patterns, AI systems support predictive maintenance in manufacturing, helping reduce unexpected downtime and extend machine lifecycles. This not only lowers costs but also improves reliability across production facilities.

2. Digital Twins and Simulation

Digital twin technology is no longer experimental; it is now central to project planning and execution. A digital twin creates a virtual model of equipment, production lines or entire plants, enabling engineers to test scenarios before implementation. In 2025, companies are using simulation to validate designs, optimise workflows and cut commissioning times. From control panel design to

robotic integration, digital twins reduce risk and support smarter factories.

3. Industrial IoT and Connectivity

The Industrial Internet of Things (IIoT) continues to grow, connecting machines, sensors and control systems across factories. With 5G and advanced edge devices now widely available, plants can share data faster and more securely than ever. Real-time visibility helps identify inefficiencies, cut downtime and enhance energy management. IIoT integration also supports cross-site monitoring, which is critical for global manufacturers managing multiple facilities in the era of smart factories.

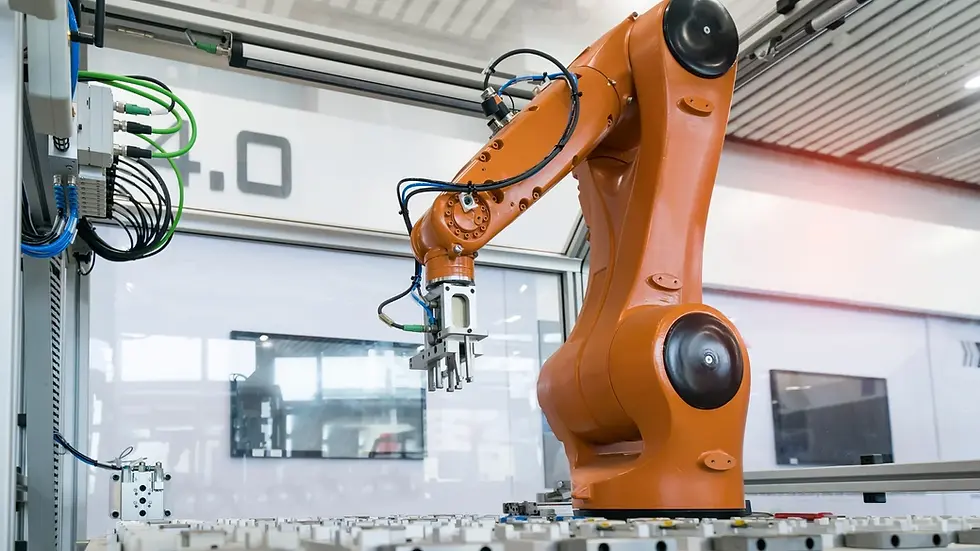

4. Collaborative Robotics (Cobots)

Robotics is expanding beyond traditional high-speed lines into collaborative environments. Cobots are designed to work safely alongside human operators, taking on repetitive or ergonomically challenging tasks. In 2025, improvements in safety sensors and intuitive programming tools make cobots more affordable and accessible for small and medium-sized enterprises. This shift allows businesses to boost efficiency while protecting workers from strain or injury.

5. Cybersecurity in Automation

With increased connectivity comes greater risk. Industrial control systems are now prime targets for cyber-attacks. In 2025, cybersecurity has become a top priority in automation projects, with manufacturers adopting secure PLCs, encrypted communication protocols and continuous monitoring tools. Compliance with international standards such as IEC 62443 is now standard practice, ensuring that automation remains both efficient and resilient against cyber threats.

Conclusion

The industrial automation landscape in 2025 is defined by intelligence, connectivity and resilience. From AI-powered predictive maintenance in manufacturing to digital twins, cobots and strengthened cybersecurity, these trends are helping manufacturers cut downtime, boost efficiency and stay competitive. As industries adopt these innovations, the line between traditional engineering and digital transformation continues to blur, creating smarter factories across every sector.